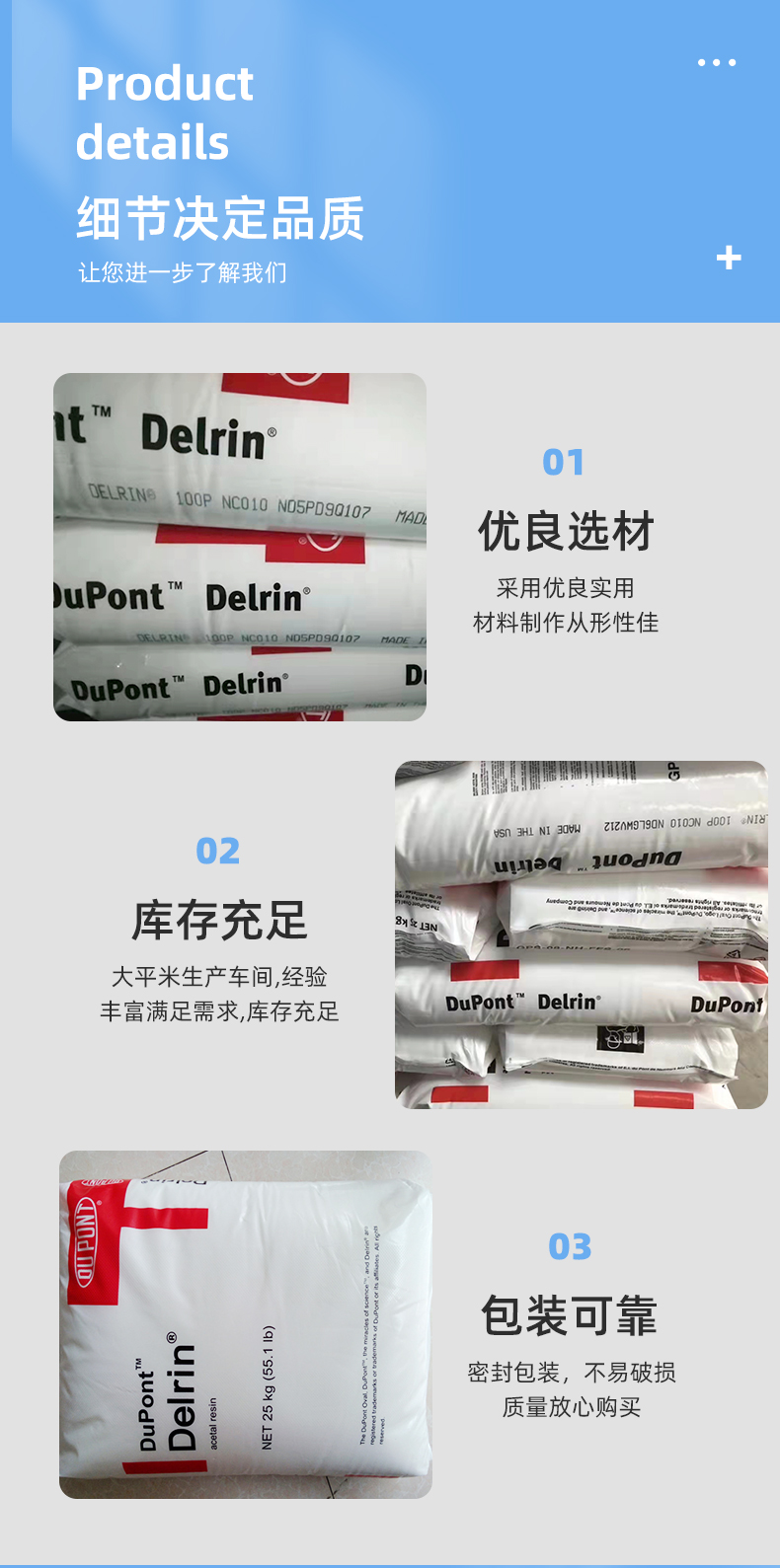

美国杜邦pa612 77g33hs1l、fe3734、77g33l、 特点:高冲击强度 ,良好的耐油脂,油,燃料,液压油,水,碱和盐,很好的耐应力龟裂性,即使遭到化学武器袭击时用来掩盖金属零件,低滑动摩擦系数和高抗磨损性,即使在干燥运行时

dupontperformance polymers zytel® 77g33hs1l nc010 nylon 612

nylon 612, glass fiber filler

dupont performance polymers

产品说明:

zytel® 77g33hs1l nc010 is a 33% glass fiber reinforced, heatstabilized polyamide 612 resin for injection molding.

information provided by dupont performance polymers

物性信息:

物理性能额定值 (公制)额定值 (英制)测试方法比重1.32 g/cc1.32 g/ccdam; astm d792密度1.32 g/cc0.0477 lb/in³dam; iso 1183填料含量33 %33 %damwater absorption0.16 %@temperature 23.0 °c

0.16 %@temperature 73.4 °f

immersion 24h; dam; astm d570

2.0 %@temperature 23.0 °c

2.0 %@temperature 73.4 °f

saturation; dam; astm d570

0.70 %@thickness 1.00 mm, temperature 23.0 °c

0.70 %@thickness 0.0394 in, temperature 73.4 °f

e 50%rh; dam; iso 62, similar to

1.8 %@thickness 1.00 mm, temperature 23.0 °c

1.8 %@thickness 0.0394 in, temperature 73.4 °f

saturation, immersed; dam; iso 62, similar to线性成型收缩率0.0010 cm/cm@thickness 1.60 mm

0.0010 in/in@thickness 0.0630 in

flow; dam

0.0020 cm/cm@thickness 3.20 mm

0.0020 in/in@thickness 0.126 in

flow; dam

0.0040 cm/cm@thickness 6.40 mm

0.0040 in/in@thickness 0.252 in

flow; dam

0.0090 cm/cm@thickness 1.60 mm

0.0090 in/in@thickness 0.0630 in

transverse; dam

0.010 cm/cm@thickness 3.20 mm

0.010 in/in@thickness 0.126 in

transverse; dam

0.011 cm/cm@thickness 6.40 mm

0.011 in/in@thickness 0.252 in

transverse; dam线性成型收缩率,flow0.0030 cm/cm@thickness 2.00 mm

0.0030 in/in@thickness 0.0787 in

dam; iso 294-4线性成型收缩率,横向0.0090 cm/cm@thickness 2.00 mm

0.0090 in/in@thickness 0.0787 in

dam; iso 294-4

机械性能额定值 (公制)额定值 (英制)测试方法洛氏硬度(r 级)118118dam; astm d785抗张强度(断裂)140 mpa@temperature 23.0 °c

20300 psi@temperature 73.4 °f

50%rh; iso 527

168 mpa@temperature 23.0 °c

24400 psi@temperature 73.4 °f

dam; iso 527抗张强度138 mpa@temperature 23.0 °c

20000 psi@temperature 73.4 °f

50%rh; astm d638

165 mpa@temperature 23.0 °c

23900 psi@temperature 73.4 °f

dam; astm d638伸长率 (断裂)3.0 %@temperature 23.0 °c

3.0 %@temperature 73.4 °f

dam; astm d638

3.0 %@temperature 23.0 °c

dam; iso 527

3.2 %@temperature 23.0 °c

3.2 %@temperature 73.4 °f

50%rh; iso 527

4.0 %@temperature 23.0 °c

4.0 %@temperature 73.4 °f

50%rh; astm d638拉伸模量7.90 gpa@temperature 23.0 °c

1150 ksi@temperature 73.4 °f

50%rh; iso 527

9.50 gpa@temperature 23.0 °c

1380 ksi@temperature 73.4 °f

dam; iso 527弯曲强度255 mpa@temperature 23.0 °c

37000 psi@temperature 73.4 °f

dam; astm d790弯曲模量6.20 gpa@temperature 23.0 °c

899 ksi@temperature 73.4 °f

50%rh; astm d790

7.00 gpa@temperature 23.0 °c

1020 ksi@temperature 73.4 °f

50%rh; iso 178

8.20 gpa@temperature 23.0 °c

1190 ksi@temperature 73.4 °f

dam; iso 178

8.27 gpa@temperature 23.0 °c

1200 ksi@temperature 73.4 °f

dam; astm d790剪切强度76.0 mpa@temperature 23.0 °c

11000 psi@temperature 73.4 °f

dam; astm d732悬壁梁缺口冲击强度1.28 j/cm@temperature 23.0 °c

2.40 ft-lb/in@temperature 73.4 °f

dam; astm d256

1.33 j/cm@temperature 23.0 °c

2.49 ft-lb/in@temperature 73.4 °f

50%rh; astm d256

10.0 kj/m²@temperature -40.0 °c

4.76 ft-lb/in²@temperature -40.0 °f

50%rh; iso 180/1a

10.0 kj/m²@temperature -30.0 °c

4.76 ft-lb/in²@temperature -22.0 °f

50%rh; iso 180/1a

11.0 kj/m²@temperature -40.0 °c

5.23 ft-lb/in²@temperature -40.0 °f

dam; iso 180/1a

11.0 kj/m²@temperature -30.0 °c

5.23 ft-lb/in²@temperature -22.0 °f

dam; iso 180/1a

12.0 kj/m²@temperature 23.0 °c

5.71 ft-lb/in²@temperature 73.4 °f

50%rh; iso 180/1a

13.0 kj/m²@temperature 23.0 °c

6.19 ft-lb/in²@temperature 73.4 °f

dam; iso 180/1a悬壁梁无缺口冲击强度45.0 kj/m²@temperature -30.0 °c

21.4 ft-lb/in²@temperature -22.0 °f

50%rh; iso 180/1u

60.0 kj/m²@temperature -30.0 °c

28.6 ft-lb/in²@temperature -22.0 °f

dam; iso 180/1u

60.0 kj/m²@temperature 23.0 °c

28.6 ft-lb/in²@temperature 73.4 °f

50%rh; iso 180/1u

70.0 kj/m²@temperature 23.0 °c

33.3 ft-lb/in²@temperature 73.4 °f

dam; iso 180/1u简支梁无缺口冲击强度6.00 j/cm²@temperature -30.0 °c

dam; iso 179/1eu

6.50 j/cm²@temperature -30.0 °c

30.9 ft-lb/in²@temperature -22.0 °f

50%rh; iso 179/1eu

8.00 j/cm²@temperature 23.0 °c

38.1 ft-lb/in²@temperature 73.4 °f

dam; iso 179/1eu

9.00 j/cm²@temperature 23.0 °c

42.8 ft-lb/in²@temperature 73.4 °f

50%rh; iso 179/1eu简支梁缺口冲击强度1.00 j/cm²@temperature -30.0 °c

50%rh; iso 179/1ea

1.00 j/cm²@temperature -40.0 °c

50%rh; iso 179/1ea

1.10 j/cm²@temperature -30.0 °c

dam; iso 179/1ea

1.20 j/cm²@temperature 23.0 °c

50%rh; iso 179/1ea

1.20 j/cm²@temperature -40.0 °c

5.71 ft-lb/in²@temperature -40.0 °f

dam; iso 179/1ea

1.30 j/cm²@temperature 23.0 °c

dam; iso 179/1ea

电气性能额定值 (公制)额定值 (英制)测试方法体积电阻率1.00e+12 ohm-cm@temperature 23.0 °c

1.00e+12 ohm-cm@temperature 73.4 °f

50%rh; astm d257

1.00e+15 ohm-cm@temperature 23.0 °c

1.00e+15 ohm-cm@temperature 73.4 °f

dam; astm d257

1.00e+15 ohm-cm@temperature 23.0 °c

dam; iec 60093表面电阻1.00e+15 ohm@temperature 23.0 °c

1.00e+15 ohm@temperature 73.4 °f

dam; astm d257介电常数3.4@frequency 1.00e+6 hz, temperature 23.0 °c

3.4@frequency 1.00e+6 hz, temperature 73.4 °f

dam; astm d150

3.7@frequency 1000 hz, temperature 23.0 °c

3.7@frequency 1000 hz, temperature 73.4 °f

dam; astm d150介电强度20.5 kv/mm@thickness 3.20 mm, temperature 23.0 °c

521 kv/in@thickness 0.126 in, temperature 73.4 °f

dam; short time; astm d149耗散因数0.020@frequency 1000 hz, temperature 23.0 °c

0.020@frequency 1000 hz, temperature 73.4 °f

dam; astm d150

0.020@frequency 1.00e+6 hz, temperature 23.0 °c

0.020@frequency 1.00e+6 hz, temperature 73.4 °f

dam; astm d150comparative tracking index>= 550 v@temperature 23.0 °c

>= 550 v@temperature 73.4 °f

dam; ul 746a

600 v@temperature 23.0 °c

600 v@temperature 73.4 °f

dam; iec 60112

热性能额定值 (公制)额定值 (英制)测试方法线形热膨胀系数 - 流动500 µm/m-°c@temperature -40.0 - 23.0 °c

278 µin/in-°f@temperature -40.0 - 73.4 °f

美国杜邦PA612 77G33HS1L